Changes in the advisory board of LF GmbH & Co. KG

Dear Ladies and Gentlemen,

effective January 1, 2024, Mr. Univ.-Prof. Dr.-Ing. Ralph Mayer (TU Chemnitz, vehicle system design) is joining the advisory board of LF GmbH & Co. KG.

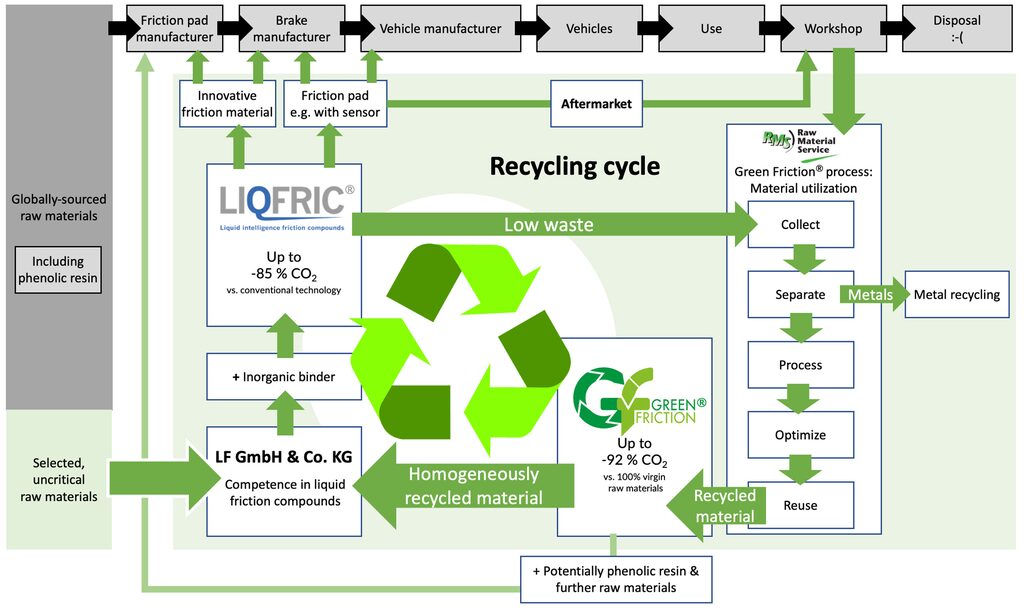

We would like to welcome Professor Mayer to our company, who will enrich our approach of delivering our LIQFRIC® system to the target market with his many years of expertise in the design of braking systems.

We would like to wish Professor Mayer a great start in our new endeavor.

The shareholders of LF GmbH & Co. KG

_____________________________________________

Veränderungen im Beirat der LF GmbH & Co. KG

Sehr geehrte Damen und Herren,

mit Wirkung zum 01.01.2024 wird Herr Univ.-Prof. Dr.-Ing. Ralph Mayer (TU Chemnitz, Fahrzeugsystemdesign) in den Beirat der LF GmbH & Co. KG eintreten. Wir freuen uns, Professor Mayer für unseren Beirat gewinnen zu können, der mit seiner langjährigen Expertise im Design von Bremssystemen unsere Marktfokussierung bereichern soll.

Wir wünschen Herrn Professor Mayer einen guten Start in unserem Haus.

Die Gesellschafter der LF GmbH & Co. KG